During my recent trip to Uganda I was able to visit some of the villages away from the towns. The state of the housing is as you see in the image above. They are built with bricks but they are very small and not very durable.

I’ve known for a while about the possibility of building houses from earth and from discarded materials. I even had the desire to build such a house for myself. I started to wonder if such a house could be constructed in these villages.

Earthships

I heard about Earthships several years ago and was captivated by how they can exist off-grid whilst costing very little to build. They generate electricity with solar, they maintain a stable temperature with natural heating and cooling. They capture rainwater and purify it for drinking and they recycle waste water and use it for fertilizer.

Could an Earthship be a solution for the villages of Africa?

Earthships use old tires to construct an outer wall, these may be available cheaply or freely, but what about glass, solar or water purification?

Earthships are designed for use by Westerners looking for a certain standard of living. These villages of Africa do not expect electricity, water or even a toilet. The cost of these things is unaffordable.

Still, I will retain this information for the future. Maybe opportunities exist for a holiday village or other such project that would bring investment into the area.

Compressed Earth Blocks

Considering the expenses involved with Earthships, I started considering other options.

The villagers of Uganda know how to make bricks, that much is clear. In front of many houses, you see a pile of bricks that are stacked for drying. This is the way they have made bricks possibly for centuries. These bricks however are not strong enough or durable enough to build large buildings.

In recent years, Ugandans have been taught that you need bricks from a kiln or cement blocks to build strong structures and that these should be bonded together using cement.

Cement is an expensive commodity and it is simply not true that it is required for building. If villagers could make bricks that are strong and durable without the need for cement then they could build bigger and stronger houses.

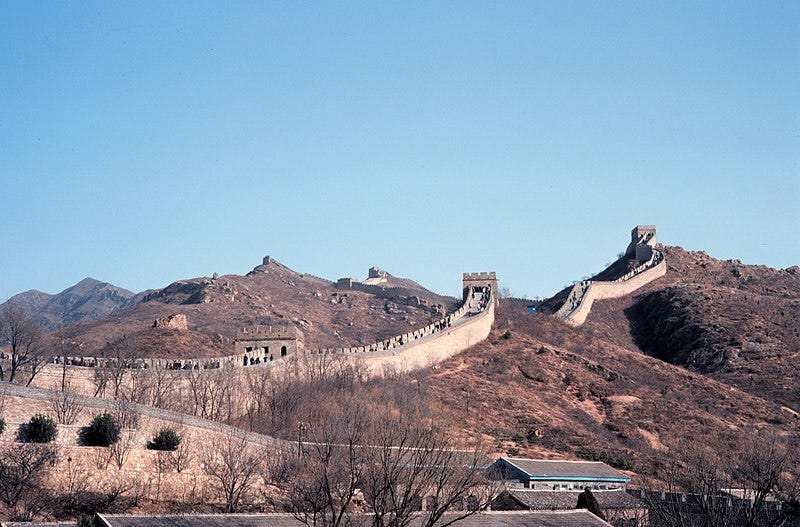

Great Wall of China - Image in Public Domain

The Great Wall of China was built centuries ago with large sections being built from earthen blocks without any cement. Other parts were build with rammed earth, and still other sections made use of a simple lime and starch mortar. The same techniques could surely be applied in Africa.

Compressed Earthen Blocks (or Bricks, CEB) look like regular bricks except that they are not baked in a kiln, rather they are compressed together in a mechanical press. There are unstabilised and there are stabilised bricks. The stabilised version needs about 10% Portland cement and then it is weatherproof. The unstabilised version can still be used for construction but it needs some protection from the elements, usually an overhanging roof and maybe a layer of cob render are sufficient.

A simple mortar of clay can be used to bind the blocks together in the construction, or a shaped mould can be used that allows the blocks to interlock without mortar.

The bricks are made using a clay sand mix with about 30% clay. Research has shown that about 90% of the Earth’s soil is suitable to be used as bricks in this manner. That means, the soil at the building site, under your feet, can be dug up, prepared as bricks and then turned into a house.

Now that is a sustainable house.

Machinery

Compressed Earth Blocks need some machinery and it can vary in cost from about $2,000 to over $100,000. The difference is the number of blocks that can be produced. For $2,000 a village could build new houses for everyone and the only thing they need is time and labour. Plus some basic education. Once they’ve built these houses they will be far more durable than what they currently have.

Once they’ve built these houses then they can go on to make brick after brick after brick and sell them for income.

Additionally, with access to steel and some basic parts and machinery, they may be able to replicate the brick-making machine itself and then sell them for lower prices to their own people without needing to import machinery.

With larger investments more automation can be brought in allowing bricks to be produced in greater quantity with less labour.

Roofing

Africans love corrugated tin roofs. Actually, I don’t know if they love them, but you certainly find them everywhere. Understandably so because they are comparably cheap yet durable. Cheap, however, does not mean free.

We need better terminology, but I have in mind a circular economy where money stays in the local environment. If money leaves the village and goes to a producer outside then that is an expense. If the money stays within the village and requires only labour then I consider that to be effectively free.

Traditional thatched roofs such as those on the round huts are exactly the sort of roofs that should be used in the villages. Westerners love thatched roofs because they look so traditional and quaint.

When a thatched roof is done properly it can easily last as long as a slate roof and it looks beautiful.

Amenities

I have not yet talked about toilets, showers, electricity etc.

Let me come back to those topics with another post as this one is already long enough.

For now, I come back to the point about education…

Education

What Africa needs is not so much a fish but to be taught how to fish. They do not need donations so that they can build buildings like we build them in the West, they need donations for education, to be taught to build businesses and to build buildings suitable for Africa!

With an investment of just a couple of thousand dollars, instead of buying a wall, they could buy a machine to make bricks that would build not just a wall but many houses besides.

Secondly education in how to do things simply yet effectively will awaken dreams in these villagers that they don’t need to be farmers but that instead, they could be builders, roofers or business owners.

If you want to support this new work, volunteer some time, or simply keep track of what we’re doing then please subscribe.